Researchers from Zurich have developed a method to produce a new type of lithium metal battery. It promises twice as much energy capacity and should still be more environmentally friendly.

Lithium metal batteries offer the potential to store twice as much energy as traditional lithium-ion batteries. However, they pose an environmental burden due to the use of fluorinated solvents and salts Research team from ETH Zurich Under the leadership of Maria Lukatskaya, a more sustainable approach was developed.

To do this, the researchers reduced the fluorine content, which increased the stability of the batteries and made them more environmentally friendly and cost-effective. But it doesn’t work completely without fluorine. Because then the batteries would be unstable and could fail after a few charging cycles or overheat and catch fire.

Environmentally friendly lithium metal battery with high efficiency

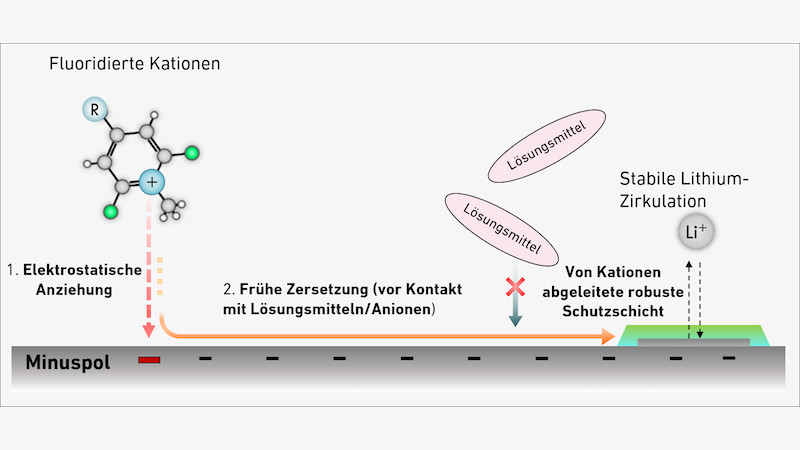

Fluorinated compounds in the electrolyte help form a protective layer around the metallic lithium on the battery’s negative electrode. This layer protects the lithium from continuous reaction with the electrolyte components, similar to how tooth enamel protects teeth. Without this protective layer, the electrolyte would quickly be used up and the battery would fail.

In addition, instead of a smooth layer, so-called dendrites would form, which could cause short circuits and fires. The ability to control the properties of this protective layer is critical to battery performance. A stable protective layer increases the efficiency, safety and service life of the battery.

The ETH Zurich team has developed a method that requires only 0.1 percent of the weight of fluorine in the liquid electrolyte – at least 20 times less than in previous studies.

New processes can be easily implemented in production lines

The new method relies on electrostatic attraction to achieve the desired reaction. Fluorinated molecules serve as transport vehicles to bring the fluorine to the protective layer. A key advantage of this method is that it can be seamlessly integrated into the existing battery production process without incurring additional costs.

The research team’s next step is to test the scalability of the method and apply it to larger cell formats such as the pouch cells used in smartphones. This could then create a real alternative to the lithium-ion batteries that are common today.

Also interesting:

- China: The world’s largest sodium-ion battery storage facility begins operations

- ION Storage Systems is about to mass produce solid-state batteries

- Energy from blood oxygen: This battery never runs out

- Researchers develop battery with supercapacitors made from chicken fat

The article New lithium metal battery: Twice the performance and still more environmentally friendly by Felix Baumann appeared first on BASIC thinking. Follow us too Facebook, Twitter and Instagram.